Tempered Glass for Shower Door Enclosure and furniture OEM Packaging

Basic Info

| Model NO. | Tempered glass |

| Thickness of Flat Tempered Glass | 5MM |

| Thickness of Curve Tempered Glass | 5MM |

| Fragment State | I |

| Technics | Physically Tempered |

| Flatness | Conforming Article |

| Usage | Building, Furniture, Home Appliance, Daily Products |

| Thickness | 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm |

| Glass Shape | Flat; Bent |

| Glass Type | Clear, Extra Clear, Pattern Glass |

| MOQ | 200 M2 |

| Other Processing | Silk Screen Print |

| Edge Work | Seam, Polish, Bevel, Matte etc. |

| Application | Door, Table Top, Partition |

| Transport Package | Playwood Crates |

| Specification | Min size: 200mmx300mm Max size: 2440mmx3600mm |

| Trademark | JH Glass |

| Origin | China |

| HS Code | 7007190000 |

| Production Capacity | 30000 Sqm/Month |

Product Description

Tempered glass for shower door enclosure and funiture OEM packagingTEMPERED GLASS FEATURES:1. 3 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed glass2. Sizes are produced as per customer request. Once tempered, it can not be cut down, drilled or any other processed edge works;3. Wind pressure resistance: The wind pressure resistance is 1.5-3 times of ordinary annealed glass4. It withstands abrupt temperature change of 220 CentigradeSPECIFICATIONS:

| GLASS TYPES | Float glass, acid etch glass, pattern glass, silkscreen print glass, low-e glass etc. |

| GLASS SHAPES | Flat tempered glass, bent tempered glass |

| THICKNESS | 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm etc. |

| SIZE | Min size: 200mmx300mmMax size: 2440mmx5800mm |

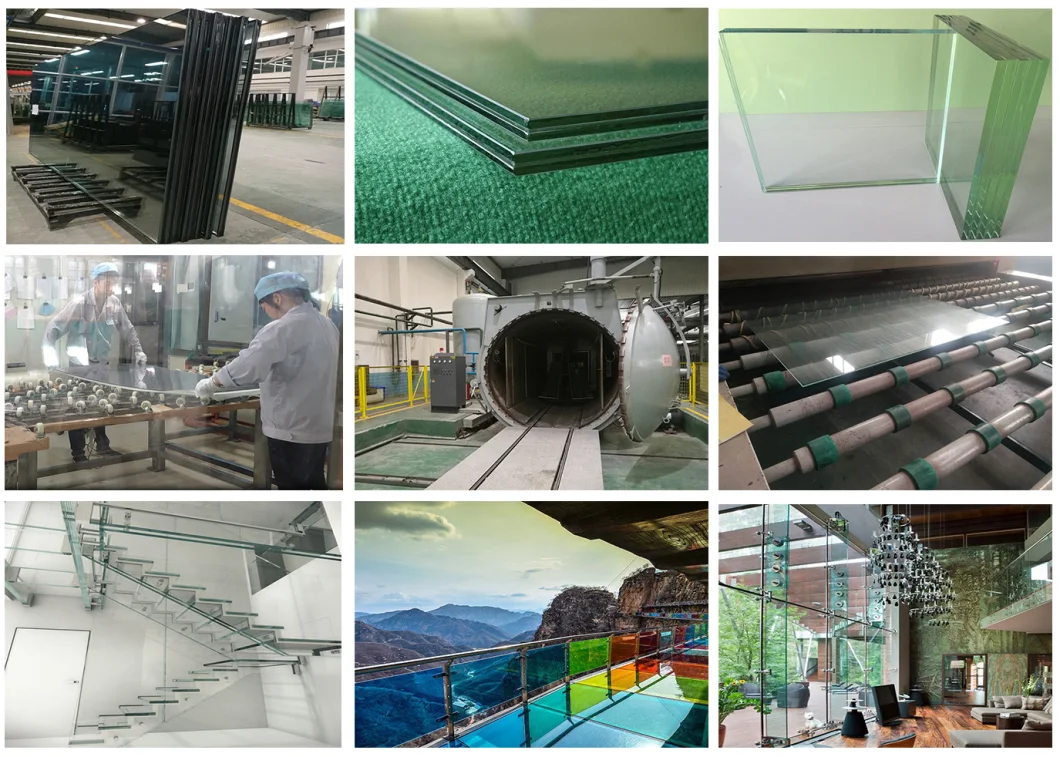

PRODUCTS: QUALITY CONTROL: Strict QC system included surface quality, flatness test, size system, impact test and fragment test.

FRAGMENT TEST:

| GLASS FRAGMENT TEST | |||

| GLASS TYPE | THICKNESS(MM) | TEST AREA | MIN. FRAGMENT QUANTITY/PIECES |

| Flat Tempered Glass | 3 | 50mm*50mm | ≥30 |

| ≥15 | 50mm*50mm | ≥30 | |

| 4~12 | 50mm*50mm | ≥40 | |

| BentTempered Glass | ≥4 | 50mm*50mm | ≥30 |

| Add: large pieces(length≤75mm) allowed in a small quantity | |||

EQUIPMENTS:Advanced equipments (flat tempered machine, bent tempered machine, cutting machine, CNC center, edge work machine, silk screen print machine, etc) to meet any shape, size, edge work. PACKAGE: Paper between each glass, plywood, carton or OEM package for safety delivery. APPLICATIONS:OTHER PRODUCTS

If also in need silk screen glass, laminated glass, shower door glass, etc, visit our PRODUCT GROUP for more information.

FAQS

Q:How about JH Glass's?quality control?

A:We have qualified works and engineers team.

Q:What about the leading time?

A:In general, the leading time is about 7-10days for sample, 30 to 40 days for bulk.

Q:How about the packing and shipping?

A:Normaly, we have carton and foam for packaging to pass topple test or drop test. If you have any other special requirements,please feel free to contact with us.

Q:Can I have our own logo on the products?

A:That's ok to have your own logo on the products. Please contact with us to make sure the detailed drawing?before placing order.

Q. Will you accept our designs?

A.Welcome! you can supply your own design or you can make a change on our design including size, material, hardware and others. Besides, we can put your logo on the package or in the product.

Q. What are your Payment terms?

A. 30% T/T deposit and the balance payment T/T before loading.

WHY CHOOSE US? 1. Most advanced glass equipment and technology2. Professional workers and QC team for providing qualified products3. Dockside warehouses beside China's main seaports to ensure the fast delivery4. Full ranges of glass and mirror products to meet your one-stop purchasing requirements5. Cooperate with many world-wide customers6. More than 15 years experience in glass and mirror manufacturing and exporting